IN THE NEWS

News & Breakthroughs in Diamond Tech

Diamond Wafer Industry Outlook

Diamond Wafer Market Set to Soar

The diamond wafer industry is rapidly growing, driven by demand in next-gen tech.

Shaping the Future of Electronics

Pioneering next-gen tech with advanced diamond-based components.

FOUNDER’S THOUGHTS

AI Is Changing the World—and It's Taking Diamond Wafers Along for the Ride

Date: 05/23/2025

Lab-Grown Diamond Heat Spreaders: 5× Thermal Performance for AI Chips

Discover how diamond heat spreaders dramatically improve AI chip performance by solving thermal bottlenecks

This week NVIDIA’s CEO Jensen Huang has confirmed the company’s commitment to TSMC, the Taiwan Semiconductor giant stating that there are no viable alternatives, ruling out partnership with Intel and Samsung Foundry In The US. NVIDIA’s statement shows that manufacturing innovation is now a chokepoint for AI growth. As thermal management becomes a bigger challenge in AI, lab-grown diamond technologies can offer a game changing solution.

Other AI chipmakers (e.g., AMD, Google, Amazon) rely on ever-smaller process nodes to pack more transistors and compute power. This creates INTENSE heat density, especially in AI accelerators, GPUs, and data center chips. As AI workloads scale, thermal management becomes the primary bottleneck—not compute architecture. That means AI innovation is accelerating but thermal management hasn’t kept up yet– enter the power of lab-grown diamonds.

Why Diamonds? Unmatched Thermal Performance

Other than looking pretty, lab-grown diamonds offer unmatched thermal conductivity, outperforming copper by 5× and silicon by 10×. Used as heat spreaders, heat sinks or substrates, diamonds can:

- Prevent overheating in AI chips

- Allow chips to run faster without throttling

- Extend hardware life (lower failure rates)

- Enable higher transistor density without overheating risks

Diverse Supply Chain in a Volitile Global Economy

Just as NVIDIA is working with TSMC’s U.S. fabs to de-risk overseas dependence, lab-grown diamond producers like Karia Technologies offer a non-Chinese, scalable, trade-accessible supply alternative. Especially important as the U.S. seeks to onshore semiconductor and thermal supply chains for AI/defense. Lab-grown diamonds grown in India, can help diversify the thermal layer of the AI chip stack.

The Future of AI and Diamonds

As AI chips grow hotter and more powerful, lab-grown diamonds will become a critical enabler of thermal efficiency, performance scalability, and hardware reliability. Just as NVIDIA leans on TSMC for transistor innovation, the AI industry will soon rely on diamond materials to push the thermal frontier.

—————————————————————————————————————————————————————————————————————————

Date: 05/12/2025

Artificial intelligence is reshaping how we live, work, and build—driving everything from automation and data insights to 3D design and autonomous systems. As AI scales, so does its hunger for power. These systems rely on chips that process billions of operations per second, and that kind of performance generates extreme heat. Traditional silicon, once the industry standard, is struggling to keep up. It’s reaching thermal and efficiency limits, slowing systems down and cutting short their lifespan.

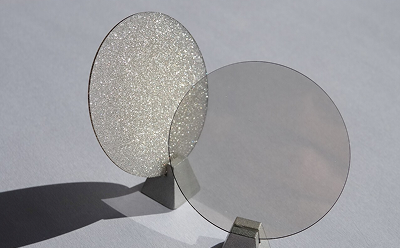

Diamond wafers are emerging as the next-generation solution. With thermal conductivity up to ten times higher than silicon, they allow chips to stay cooler, run faster, and last longer. For high-power, high-frequency applications—like AI, quantum computing, 5G/6G, and aerospace—this isn’t just an upgrade, it’s a necessity. At Karia Technologies, we’re building that future with lab-grown single and polycrystalline diamond wafers, heat sinks, and powders engineered to meet the performance demands of tomorrow’s technologies.

And AI isn’t just driving demand—it’s also reshaping how we market and tell our story. We’ve used generative tools like ChatGPT to design 3D product renders, visuals, and branded content that would’ve taken weeks with traditional creative teams. With the right prompts, we’ve brought our diamond substrates to life—shimmering single crystals, precision-cut wafers, heat sinks built for the next era of computing—all imagined and executed through AI.

AI is pushing hardware to evolve, and diamond substrates are rising to meet the challenge. At Karia Technologies, we’re proud to be part of this transformation, powering innovation with precision that lasts.